Micro X-ray CT research example: particle size analysis

Micro X-ray CT is an excellent method for measurement of bulk particles, such as sand, metal powders used for additive manufacturing, or other separate particles.

The sample preparation is usually as simple as filling a small straw with the loose powder. After using x-ray tomography to create a 3D image of the bulk powder, each individual particle can be visualised and measured in 3D. Measurements such as size, position, and shape are readily available and statistics for hundreds to thousands of particles can be generated with a single μCT scan.

Example: measuring particle size in glass beads

Example: feedstock powder for additive manufacturing

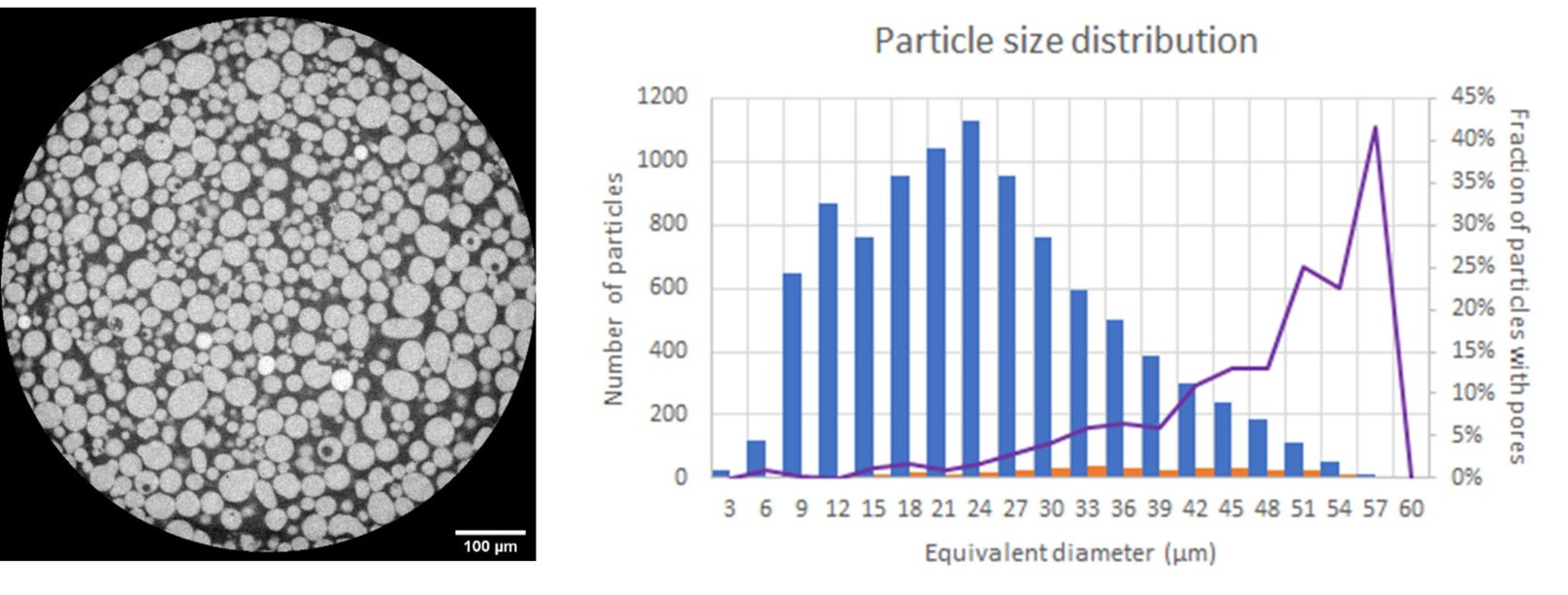

In our current research, we use this method for quality control of feedstock powders for AM printing. Powders are checked for particle size and shape distributions, which can affect the flow of the powder in the printer. Pores inside the powder particles can also be identified - pores can still be present in the build particle and affect the strength of the final printed part. Impurities of a different material can also be detected, given enough difference in x-ray attenuation, for example tungsten inclusions in titanium powder.

The image below shows a cross-sectional slice of the 3D CT data set, and the resulting particle size distribution after analysis of the data. Porosity inside the particles has also been quantified and shown with respect to the size of the particles in the distribution.

This method is generally appropriate for particles of approximately 40 um - 2 mm. Smaller particles might be possible to scan, but identification of individual particles becomes difficult due to limits to the resolution and image contrast.

Read more in the recently published A Review of Particle Size Analysis with X-ray CT.

The video shown here was created with Fiji and Drishti from Zeiss Xradia Versa data.