Analysis of in-layer density variations and particle size segregation in binder jet printed parts

Binder jet printing cements loose particles into manufactured parts. Micro-X-ray-CT can be used to investigate in-layer density changes and particle size segregation.

Binder Jet Printing is an additive manufacturing technology where loose powder particles are first cemented together, and then sintered into a final manufactured part. Irregularities of the powder-bed, such as changes in packing density and particle size distribution, can affect the quality of the final product. These changes are generally difficult to study due to the 3D nature of the powder bed, but Micro-X-ray-CT can be used to scan the parts before sintering and analyse the packing density and particle size distribution at each location.

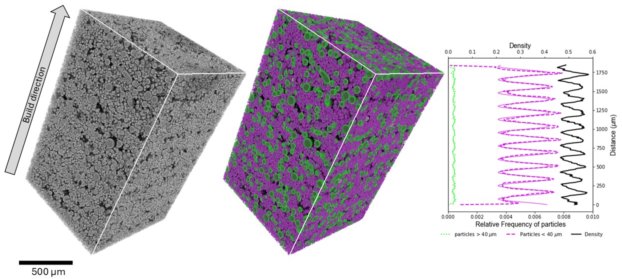

In our recent research, we used Micro-X-ray-CT to investigate how in-layer changes in the packing density are caused by size-based particles segregation. Analysis of the tomographic data allows to measure the size and position of each powder particle and calculate values such as packing density and particle size distribution. Throughout the printed samples, the packing density varies with a frequency corresponding to the layer thickness. A similar periodic change can be seen in the particle distribution within each layer - smaller and larger particles accumulated preferentially at the opposite side of each printed layer.

In the figure above, the packing density variations can be seen to correlate with preferential location of smaller (< 40 microns, purple) and larger ( > 40 microns, green) particles. The distribution of particles of both sizes, as well as the packing density, shows a sinusoidal pattern with a frequency that correlates to the print layer height.

Further details are available in our recent publication: Micro-X-ray-CT for analysis of particle size segregation during powder spreading in Binder Jet Printing

Images shown here were created with Drishti from Zeiss Xradia Versa 620 data.