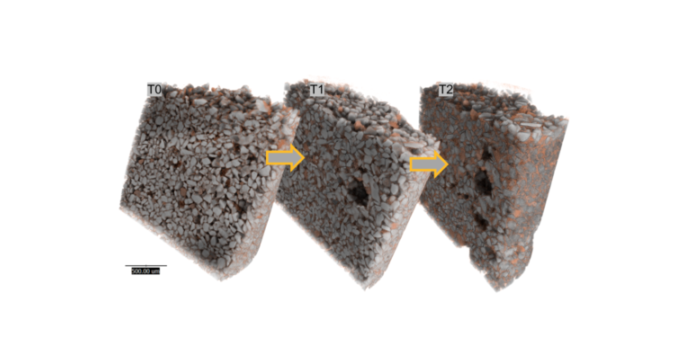

Current research examples using the Zeiss Xradia Versa 620

The Zeiss Xradia Versa 620 is predominantly used for research from the fields of manufacture, energy, and healthcare. Below are highlighted examples of current research that has been carried out with help of the instrument.