Feature: Will we ever have a robo-chemist?

Published on

This is the first of a number of feature articles exploring the new approach that the Materials Innovation Factory (MIF) will bring to materials science.

Robo-chemists may sound like science fiction, but scientists at the University's Materials Innovation Factory (MIF) plan to make them an everyday part of chemistry research and use them to fast forward advances in materials science.

From the automated to the autonomous

Primitive forms of the robo-chemist were first developed by organic chemists and pharmaceutical scientists. These have been dubbed synthesis machines. Although their complexity is increasing and some are now able to respond to reaction results, in general, they are programmed to follow instructions and make molecules as directed.

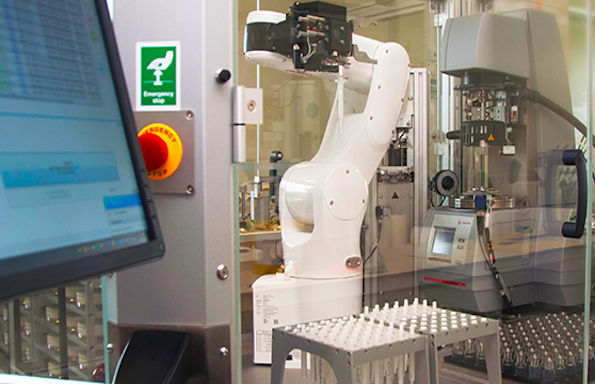

Over the last decade, robotic systems have also been finding their way into material chemistry labs. These are often floor-standing machines that carry out automated reactions and materials synthesis. They can do hundreds of experiments in the time it takes their human counterparts to complete just one. But, at the moment, they just follow orders and have no real ability to make decisions.

At the University of Liverpool, materials chemists are working with computer scientists and robotics experts to develop the robo-chemists’ intelligence. They want to create autonomous robo-chemists and use them to drive materials science research forward. These robots must be smart and able to make their own, informed decisions.

Robo-chemists also need to be able to communicate, both with one another, with lab instruments, and with us. This information sharing is key for accurate decision making. And finally, for a robo-chemist to work in an automated lab, it needs to be able to locate and carry chemicals and equipment from one place to another, safely and accurately.

The University of Liverpool’s Materials Innovation Factory (MIF) is the perfect place to develop the robo-chemist. This purpose-built facility is where robotics are being used, together with computer-aided materials design approaches, to maximise the use of our scientific infrastructure.

With access to perhaps the highest concentration of automated chemistry lab equipment in the world, university researchers and industry have a unique opportunity to collaborate and advance materials science. It is manned by fully trained staff and is open access, meaning anyone can make use of the state-of-the-art devices available, to experiment and accelerate discoveries.

Developing decision making

We are at the beginning of a long journey when it comes to making our automated robo-chemists autonomous. Scientists involved in their development are independently focusing on different parts of the puzzle. In the years to come, they will bring these together for further optimisation and development.

Professor Andy Cooper, Academic Director of MIF, says, “Initially, we are focusing on making a robot capable of semi-autonomous discovery. It will be able to synthesise a few hundred materials at a time and measure their properties. Then, it will be able to decide which materials to make, or what experiment to do next.” From this point, he hopes to be able to develop the robots so that they can move independently beyond this first set of experiments. This is one goal of a major ten-year project in Liverpool, at the Leverhulme Centre for Functional Materials Design.

Image: Professor Andy Cooper

To carry out consecutive experiments, robots rely on decision making software. Professor Katie Atkinson, Computer scientist at the University of Liverpool, is developing automated intelligent reasoning techniques to integrate into robo-chemists’ systems. She says, “Artificial Intelligence, or AI, is all about decision making. A robot needs to be able to look at a goal and decide how to get there. To do this, they need to solve problems and to reason. We want give them the capability to get to their goal without spelling out every step along the way.”

Robo-chemists with artificial intelligence

But, creating a robot that can reason will not make it a chemist. The decisions it makes will not, initially, be based on knowledge or interpretation of chemistry. Professor Cooper adds, “Here, the robot is relating inputs to outputs, or composition to measured function. A real robo-chemist would be able to form a chemical hypothesis from knowledge of the literature. This is true AI, and although it is a goal, we are a long way from achieving it.”

Through interdisciplinary collaboration facilitated by MIF, Professor Cooper is hoping to make some headway and teach an AI system chemistry. He explains, “The IBM Watson machine showed us that it can learn certain areas of biology and medicine. The problem with chemistry is that information is presented in many different ways. Structures are drawn as diagrams and names are often non-standardised. Human chemists often need to interpret graphs or microscope images and make subjective decisions. Writing software that can imitate this is not a simple task.”

There are a number of different techniques that can be combined to achieve this vision of a robo-chemist. Professor Atkinson specialises in computational models of argument and explains, “To learn how to make a decision, the robot will need to use techniques in combination as there are often multiple parts to a problem.

Natural language processing techniques, such as data mining and machine learning, can help interpret the different forms of chemical data. This could then be reasoned about through the argumentation approach.” She thinks that this approach will be beneficial as the robots’ reasoning can be followed, and we can then understand how and why a robot came to a specific decision. We can use this to develop the robots’ communication techniques and improve their decision making capabilities.

A walking, talking, robo-chemist

Another part of the robo-chemist puzzle centres around its robotics. The machine needs to be able to work in a laboratory setting and interact with chemicals, other robots and humans. This is where the work of Karl Tuyls, Professor of Computer Science and of BioInspired Robotics and Autonomous Systems at the University of Liverpool, comes to the fore.

Professor Tuyls and his team are currently focusing on creating one robot capable of moving within a space and manipulating samples. The biggest challenge will begin when two robots meet and need to work together. They also need to be developed to recognise samples, select appropriate ones and use their robotic arms to move them with accuracy.

With a background in machine learning and robotics, he says, “We need software systems for robots that can learn and adapt to new circumstances by themselves - just like a human. The robot must be capable of behaving intelligently in a dynamic and uncertain environment, the lab.” Professor Tuyls is using simultaneous localisation and mapping (SLAM) techniques to teach the robo-chemists to know their position in a lab and to map the lab space so that they can move around.

He adds, “A robot active in a lab will have an on-board computer and a neural network – also like a human. Using sensory information taken from lasers that act like eyes, it will run probabilistic techniques to solve localisation and navigation problems.” He notes that the robots will be able to communicate with one another, sending information, for example via Wi-Fi, to help avoid collisions and facilitate robotic collaboration.

Professor Atkinson is working on the development of communication capabilities for the robots and lab instruments. She says, “We are making use of nDrites which are smart agent enablers. These will be integrated with the laboratory resources and the robots. They are an intelligent form of middleware, developed as part of a knowledge transfer project with CSols, that will provide communication channels so that autonomous agents can interact with laboratory instruments, and tell them what to do.”

Robo-chemists for advanced materials design

In the long term, the robots built by Professor Tuyls and co-workers will be integrated with the reasoning software under development by Professor Cooper, Professor Atkinson and their teams. With the aid of related projects in other UK universities, such as the Leverhulme Centre for the Future of Intelligence, we should see the emergence of true artificially intelligent robo-chemists within the next few decades.

This new collaboration has been brought about through the University of Liverpool’s Materials Innovation Factory and Leverhulme Centre for Functional Materials Design, which are co-directed by Professor Cooper.

Professor Cooper concludes, “Materials space is huge. As humans, we do not have the capacity to explore it all. Robots could help us cover more ground and make discoveries faster.” He adds, “For example, there is no physical reason why room temperature superconductors should not exist, or why we cannot produce hydrogen fuel efficiently from water using sunlight.

There are an almost unlimited number of combinations of combinations of molecules and elements available in materials design space, and it might be just that we have not yet put the right combinations together to make these materials. Robo-chemists could free up valuable chemist thinking time so that we can narrow down the options and find one.” With the technology it is developing, MIF is set to be the location for many of such materials discoveries.

The Materials Innovation Factory is a unique public/private partnership between the University and Unilever supported by the Higher Education Funding Council for England, as part of the UK Government’s Research Partnership Investment Fund.

For further information on the MIF, please visit this website.

Image credit: SG Photogaphy