Adaptix Wins Award for Innovative X-Ray Technology

Oxford-based technology company Adaptix has been recognised as the most exciting emerging technology at this year's Aerospace Technology and Innovation Awards. The accolade highlights the company's groundbreaking approach to low-power 3D X-ray imaging, with potential applications spanning multiple industries.

The Aerospace Technology Institute celebrated Adaptix's advances in Non-Destructive Testing (NDT), a critical process for ensuring the quality of advanced materials. As the aerospace sector moves towards developing lightweight materials to support the UK's net zero strategy, Adaptix's technology offers a promising solution. Their innovative imaging technologies allow manufacturers to identify potential production faults early, significantly reducing waste and improving efficiency.

In a strategic collaboration with Cranfield University, Adaptix has been scaling up its imaging technology to tackle complex challenges in aerospace manufacturing. The team has developed capabilities to image large structural components, including aircraft wing sections, doors, and external layering, with unprecedented precision and minimal resource consumption.

Simultaneous to their NDT activities, Adaptix is making significant strides in healthcare through a separate collaboration with the University of Liverpool. The QUASAR Group, led by Professor Welsch, has secured £400,000 in funding from the Science and Technology Facilities Council to develop the OptiX project. This innovative initiative aims to create a novel chest imaging device that can provide low-dose 3D imaging directly at a patient's bedside.

Contemporary 3D imaging systems like CT scanners, while crucial to modern healthcare, often come with significant limitations. They typically involve high radiation exposure, substantial infrastructure costs and the complexity of moving critical ill patients to the scanner. There are mobile X-ray systems that can be brought to a bedside but these only give 2D images. The OptiX project addresses these challenges by exploring how 3D images can be generated at the bedside by firing low-power X-rays from an array of positions from a compact, mobile device..

The technology's potential is far-reaching. By reducing radiation dosage and making 3D imaging more accessible, it could revolutionise diagnostic procedures, potentially enabling more frequent and less invasive lung cancer screenings and improving emergency medical imaging.

Central to this innovative work has been the support of LIV.INNO, a centre for doctoral training led by Professor Welsch. Through LIV.INNO's collaborative model, Physics PhD students develop advanced data science skills while working directly with industry partners like Adaptix. The QUASAR Group, in collaboration with Adaptix, has developed sophisticated computer simulations that are critical to optimising the new imaging technology.

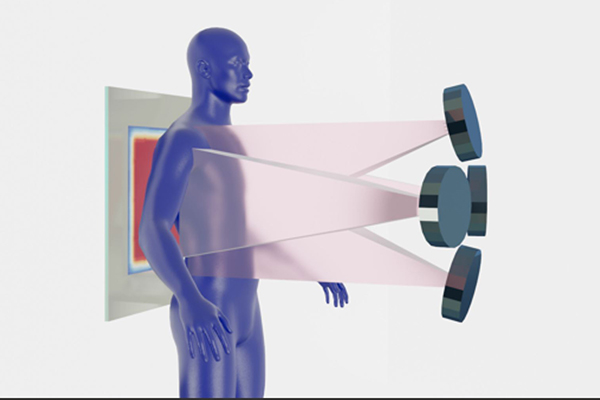

Visualisation of a chest digital tomosynthesis device, simulated by the QUASAR Group. X-rays propagate from multiple panels to irradiate a patient. The detector illumination map is used to optimise the design of the device.

These simulations represent a comprehensive approach to technological refinement. Using advanced computational techniques, the QUASAR team has created a suite of simulation tools that address multiple critical aspects of X-ray imaging technology. The simulations optimise electron beam energies and target compositions, allowing researchers to fine-tune the X-ray generation process. Equally important are the radiation dosage simulations, which model the potential impact on specific organs, enabling the development of safer imaging techniques. Genetic algorithms are used to optimise the overall system arrangement, a computational approach that mimics natural selection to identify the most efficient design configurations.

Dr Steve Wells, Chief Technical Officer at Adaptix, explains “Our collaboration with the QUASAR Group has been instrumental in driving forward Adaptix's innovative imaging technology. The advanced simulations model our electron beams, X-ray spectra and design geometries. This enables us to quickly select promising designs and avoid wasting time on expensive and time-consuming physical experimentation of less optimal designs. This partnership showcases the power of combining academic expertise with industrial innovation to create transformative technologies with real-world impact.”

This recognition at the Aerospace Technology and Innovation Awards underscores Adaptix's innovative approach and its potential to drive significant technological advancements across multiple sectors.